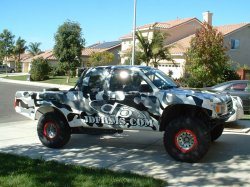

Back in 2003 I sold my class 7 Toyota and bought a stock 1995 2wd Toyota T100 to build as a prerunner. I wasn't racing any more because of the cost and wanted to build a truck that I could use to go film at races and other off road trips. This thread will start from the beginning of the build and show the changes that were made over the years.

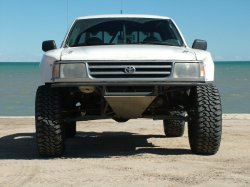

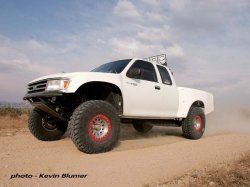

The T100 how it looks today:

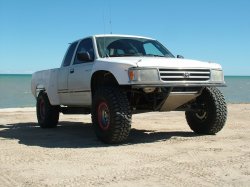

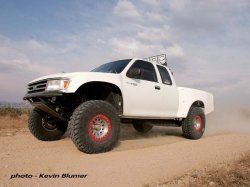

When it was finished in 2005:

Original build specs from 2005 with notes of the current setup:

Owner: Curtis Guise

Builder: Curtis Guise & Mark Newhan

Vehicle: 1995 Toyota T100, 2wd

Debut: Jan. 2005

Wheelbase: 121 inch

Trackwidth: 84 inch

Engine: Toyota 3.4 V6, TRD Supercharger with URD kit.

Transmission: Toyota Automatic

Brakes: Wilwood 4 piston Superlights (currently 6 piston Wilwoods)

Steering: GM saginaw box, stock T100 pump.

Front Suspension:

Style: A-arms designed by Mark Newhan

Travel: 19"

Shocks: SAW 14" x 2.0 coil-over, 14" x 2.5 by-pass (currently FOX 2.5" coil-over & bypass shocks)

Rear Suspension:

Style: 4 link

Travel: 25 inch

Shocks: SAW 16" x 2.5 coil-over, 18" x 3.0 by-pass (currently FOX shocks)

Wheels: 15x7 American Racing beadlocks

Tires: 35x12.50 Goodyear MTR's (currently 37" Goodyear MTR's)

Rear axle: 9" Stock Car Products housing and hubs, 35 spline axles. (Currently a 4" Dirt Tech housing with 40 spline axles)

Lights: Hella 4000's converted to VisionX HID (currently newer style Vision X HID's and Vision X lightbar on the bumper)

GPS: Lowrance 6500c (currently use an iPad)

Radio: Kenwood

Intercom PCI 4 link

Seats: Beard (currently MasterCraft seats)

Restraints: Crowe (currently MasterCraft)

Body: Hanneman Fiberglass hood, fenders and bedsides

The T100 how it looks today:

When it was finished in 2005:

Original build specs from 2005 with notes of the current setup:

Owner: Curtis Guise

Builder: Curtis Guise & Mark Newhan

Vehicle: 1995 Toyota T100, 2wd

Debut: Jan. 2005

Wheelbase: 121 inch

Trackwidth: 84 inch

Engine: Toyota 3.4 V6, TRD Supercharger with URD kit.

Transmission: Toyota Automatic

Brakes: Wilwood 4 piston Superlights (currently 6 piston Wilwoods)

Steering: GM saginaw box, stock T100 pump.

Front Suspension:

Style: A-arms designed by Mark Newhan

Travel: 19"

Shocks: SAW 14" x 2.0 coil-over, 14" x 2.5 by-pass (currently FOX 2.5" coil-over & bypass shocks)

Rear Suspension:

Style: 4 link

Travel: 25 inch

Shocks: SAW 16" x 2.5 coil-over, 18" x 3.0 by-pass (currently FOX shocks)

Wheels: 15x7 American Racing beadlocks

Tires: 35x12.50 Goodyear MTR's (currently 37" Goodyear MTR's)

Rear axle: 9" Stock Car Products housing and hubs, 35 spline axles. (Currently a 4" Dirt Tech housing with 40 spline axles)

Lights: Hella 4000's converted to VisionX HID (currently newer style Vision X HID's and Vision X lightbar on the bumper)

GPS: Lowrance 6500c (currently use an iPad)

Radio: Kenwood

Intercom PCI 4 link

Seats: Beard (currently MasterCraft seats)

Restraints: Crowe (currently MasterCraft)

Body: Hanneman Fiberglass hood, fenders and bedsides

Last edited: